Kason Corporation has an established history of separating itself from the competition with custom processing solutions, from high-capacity vibratory screeners, compact centrifugal sifters, versatile circular fluid bed processing equipment, durable static sieve screening equipment, and more. The Kascade recycling deck for circular vibratory separators reflects Kason’s longstanding commitment to delivering high-performance industrial processing equipment, cost-effective replacement parts, and expert field service for a wide range of applications and industries.

Effective, High-Capacity Screening

Effective, High-Capacity Screening

“The [Kascade] deck easily handles the increased production in less time. If anyone’s removing solids from liquids, this is the way to do it.”

– AgriEnergy Resources Production Manager Merlin Nussbaum

One of the top benefits of the Kascade is its inherent ability to maximize screening capacity and promote effective separation, even when screening challenging materials.

Kascade recycle decks can double the available screening surface in sorting, separating, and dewatering applications where actual surface area restricts screening capacity. They can also address product back-up when oversize volumetric rates are high enough to prevent materials from discharging quickly and efficiently.

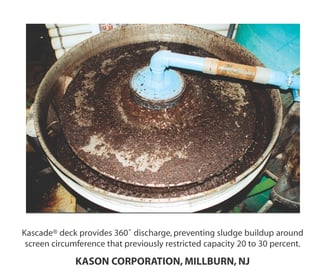

On single-deck circular vibratory screeners, the Kascade External Recycle Deck can address material transport problems. By discharging oversize particles in a 360˚ cascade pattern, the Kascade makes use of the full screen area, allowing for more efficient overall separation. Screened material falls onto a high-capacity discharge ramp before being discharged through an oversized spout. By screening with a single particle bed depth, screening efficiency is increased.

The Kascade Internal Recycle Deck can be used to drastically increase multiple deck sizing capacities. Coupled with an auxiliary discharge frame, the Kascade Internal Recycle Deck for multi-deck vibrating screeners offers radical throughput performance.

In the video below, watch as a K24-SS 24" Vibroscreen Circular Vibratory Screener employs a Kascade screening deck to quickly separate pellets. The 360-degree peripheral discharge deck promotes rapid pellet scalping and dedusting.

Real-World Challenge: Kason Increases Screening Capacity Threefold

A client processing pellets on a standard configuration two-deck 72” diameter circular vibratory screener needed to boost their screening capacity. When they contacted Kason, they were screening pellets at a rate of 15,000 pounds per hour.

A Kascade Internal Recycle Deck was quoted for their circular separator to achieve a higher throughput. By retrofitting their existing vibratory screener with Kason Corporation’s cost-effective 360˚ cascade screening deck, the customer more than tripled their screening capacity at a nominal cost, screening pellets at rates upwards of 55,000 pounds per hour.

Custom Screening Equipment and Retrofitting Options

Kason’s Kascade internal and external recycle decks can be used for screening liquids and solids in food and beverage, chemical processing, pharmaceutical, and other industries.

Kascade decks for circular vibratory sifters are offered in diameters ranging from 40” to 72” (1016mm to 1829mm), one of many custom options for new models of Vibroscreen circular vibratory screeners.

The Kascade can also be ordered from Kason’s lineup of vibratory screener aftermarket parts. Retrofit kits can boost the screening capacity of existing Vibroscreens and other makes and models of circular vibrating sieves.

Options are available to meet 3-A, USDA, BISCC, and other sanitary standards, and can be rapidly disassembled for thorough washdown.