Kason was thrilled to have been part of the official opening of the new AHS-AMP facility in Darwen, Lancashire last week. We were delighted to show our guests the 60,000 sq ft facility, which includes manufacturing space, a fully contained test bay and modern offices, as well as provide them with a guided tour.

Kason Showcases Innovative Equipment at Opening in Darwen UK

Topics: Centrifugal Sifters, Mixers, Blenders

7 Questions to Evaluate Material Processing Equipment Manufacturers for Quality, Price and Value

How You Can Secure Competitive Prices and Fast Lead Times on Durable Processing Equipment

To maintain a competitive edge in the material processing industry, partnering with a supplier who provides three key benefits – a good price on equipment, long-lasting performance, and fast lead times – is essential.

Topics: Centrifugal Sifters, Vibratory Screeners

KASON AND MARION BOOST BLENDING CAPACITY AT ALMAC PHARMA SERVICES NORTHERN IRELAND

Topics: Centrifugal Sifters, Mixers, Blenders, case study

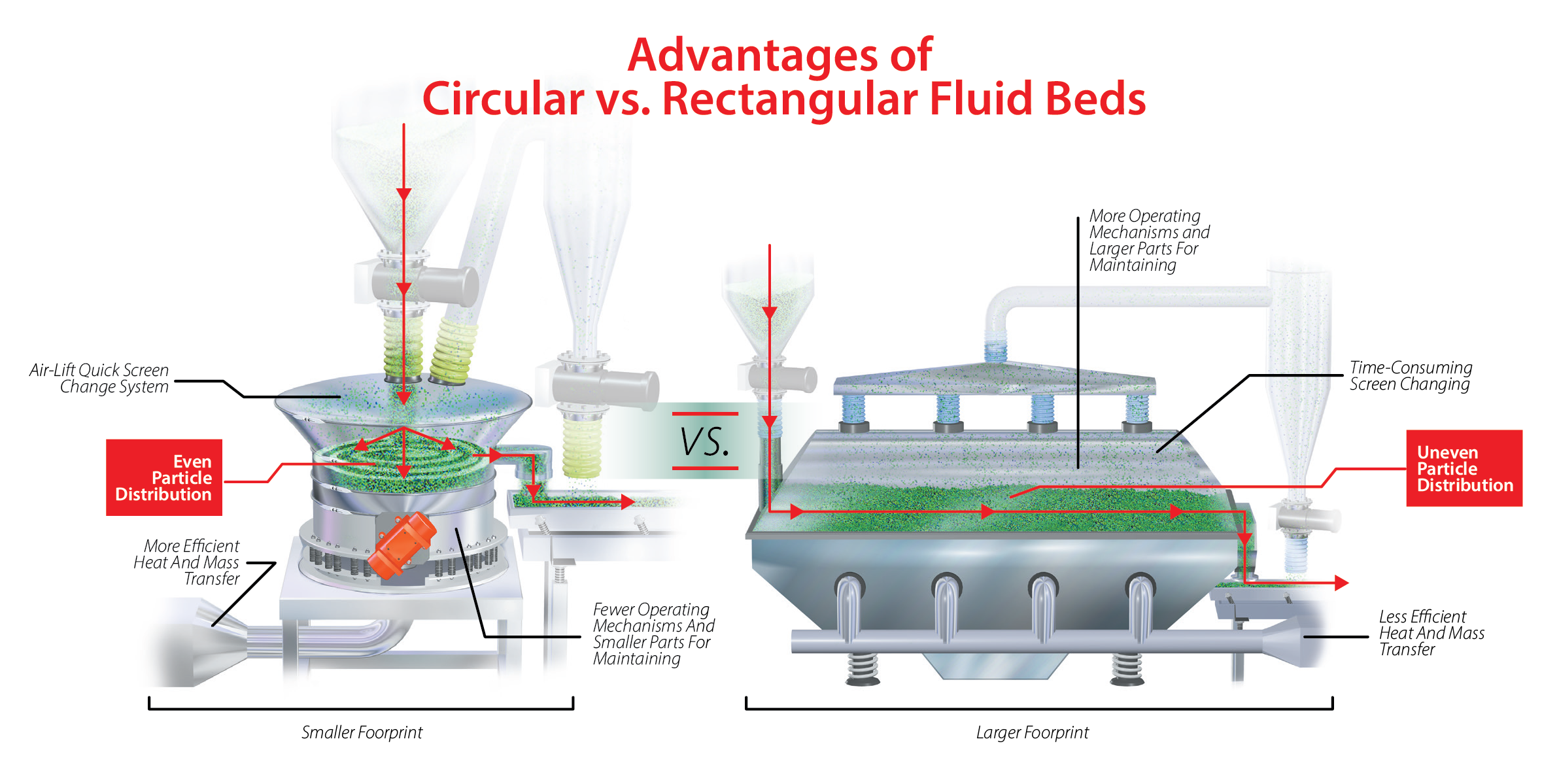

When exploring the available fluid bed options, the first consideration should be its shape. Should you go with a traditional rectangular fluid bed or a more modern circular design?

Topics: Fluid Bed Processors, Thermal Processing

Coffee Producers Boost Production with Sifters and Screeners

Quality and efficiency are paramount in the highly competitive coffee industry. Any process improvement that can help increase product purity, reduce downtime and streamline operations is essential for staying ahead of the competition and ensuring long-term success.

Topics: Centrifugal Sifters, Vibratory Screeners, Pet Food Industry, Coffee Industry

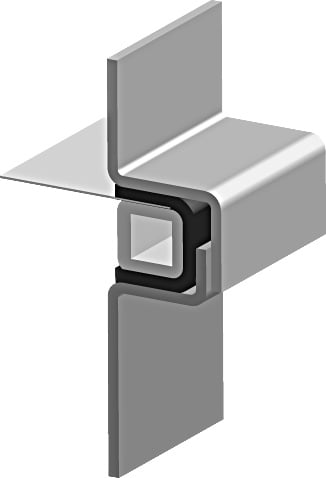

VIBROSCREEN Circular Vibratory Screeners efficientlyscreen, separate, and dewater bulk solids on a batch or continuous basis. While standard high-performance circular vibrating separatorsareavailable for shipment in as little as six weeks, circular screenersare fully customizable to meetunique and challenging processing needs. One such custom option is Kason’s innovative gap-freedesign, which drastically reduces contamination and prevents material buildup.

Gap-free circular vibratory separators feature an external, interlocking flange configuration between screen frames, secured by quick-disconnect clamps. The support ring of the internal screen is fully enveloped and allows the screen’s wire mesh to extend to the interior walls of the frame, removing the gap between the screen ring and the frame wall. (In conventional screeners, this is where material tends to accumulate.) This is especially useful in powder processing and applications with stringent sanitary requirements.

Topics: Circular Vibratory Screeners, Aftermarket & Spare Parts, Custom Options

How to Upgrade Your Screener into a High Capacity Powerhouse

Kascade Screening Decks for New and Existing Circular Vibratory Screeners

Kason’s high-capacity Kascade screening deck is a low-maintenance choice to boost screening capacity for new circular vibratory screeners, but did you know that the Kascade is also part of Kason’s extensive range of high-performance spare parts for vibrating sifters? It can be used in solids/solids separation (e.g., applications that call for the removal of fines in materials like plastic pellets, cereal, pet food, fertilizer, salt, sugar, etc.), as well as liquid/solids separation (e.g., dewatering high volumes of solids).

Topics: Circular Vibratory Screeners, Aftermarket & Spare Parts, Custom Options

Kascade Screener Eliminates Fines and Reduces Product Waste

In solids-solids separation applications that call for careful material handling and the removal of fines, circular vibratory screeners equipped with Kascade 360˚ cascade screening decks effectively classify materials while removing fines. Once installed, the Kascade also requires minimal maintenance to remain in good operating condition. It can be quickly and easily disassembled for thorough wash-down between production runs, increasing productivity while reducing labor requirements and cost-prohibitive downtime.

Topics: Circular Vibratory Screeners, Aftermarket & Spare Parts, Custom Options

Animal Feed Manufacturer Achieves Higher Screening Capacity

High-Capacity, Small-Footprint Screening

The Kascade screening deck for circular vibrating separators is designed to maximize screening throughput. This feature can be especially beneficial in solids-solids separation and dewatering applications where floorspace restrictions apply. Compared to standard circular vibrating sifters of equivalent diameters, Kason VIBROSCREEN Circular Vibratory Screeners with Kascade decks can increase screening capacity by 60-160%.

Topics: Circular Vibratory Screeners, Aftermarket & Spare Parts, Custom Options

Posts by Tag

- Circular Vibratory Screeners (14)

- Aftermarket & Spare Parts (12)

- Centrifugal Sifters (9)

- Custom Options (6)

- Fluid Bed Processors (4)

- Industrial Screeners & Industrial Sifters (4)

- Vibratory Screeners (4)

- Mixers (3)

- Pet Food Industry (3)

- Screening Questions (3)

- Technical Articles (3)

- Aquaculture Industry (2)

- Blenders (2)

- Cannabis & Hemp Industry (2)

- Sanitary Equipment (2)

- Thermal Processing (2)

- Case Histories (1)

- Coffee Industry (1)

- Distillery & Brewery (1)

- case study (1)

-2.webp)