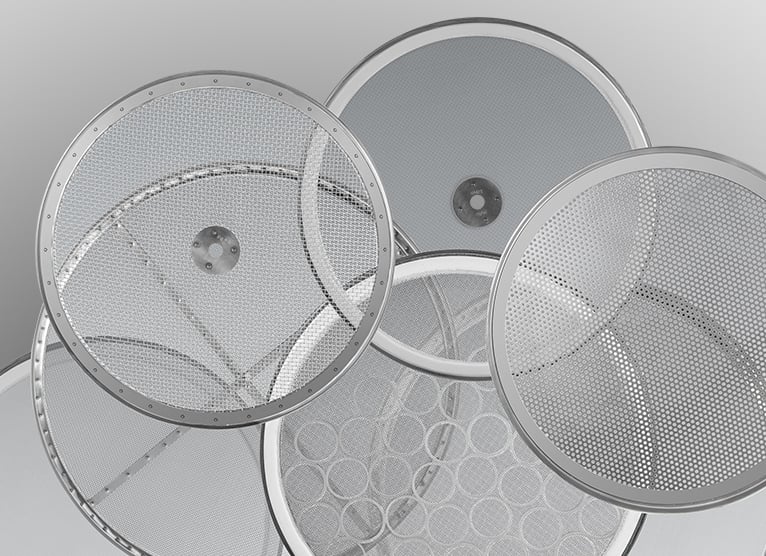

The Kason Kascade recycle deck for vibratory screeners exemplifies Kason’s commitment to delivering high-performance industrial processing equipment for screening, separating, classifying, and dewatering in industries like food and beverage, pharmaceutical, and chemical processing.

Topics: Circular Vibratory Screeners, Aftermarket & Spare Parts, Custom Options

Boost Screening Capacity and Efficiency with a Kascade Deck

Kason Corporation has an established history of separating itself from the competition with custom processing solutions, from high-capacity vibratory screeners, compact centrifugal sifters, versatile circular fluid bed processing equipment, durable static sieve screening equipment, and more. The Kascade recycling deck for circular vibratory separators reflects Kason’s longstanding commitment to delivering high-performance industrial processing equipment, cost-effective replacement parts, and expert field service for a wide range of applications and industries.

Topics: Aftermarket & Spare Parts, Vibratory Screeners, Custom Options

When it comes to pet food production, the pursuit of excellence is paramount. Every kibble, treat, and meal that reaches our pets' bowls should present the highest quality, nutrition, and safety standards.

Topics: Mixers, Pet Food Industry

Want to make sure you are getting the right parts – and the best performance – for a sifter, screener or related type of processing equipment?

Topics: Industrial Screeners & Industrial Sifters, Centrifugal Sifters, Aftermarket & Spare Parts

Having your material processing equipment installed correctly the first time doesn’t happen by chance.

Topics: Industrial Screeners & Industrial Sifters, Aftermarket & Spare Parts

4 Screener & Sifter Parts that Will Save You in an Emergency

Topics: Industrial Screeners & Industrial Sifters, Aftermarket & Spare Parts

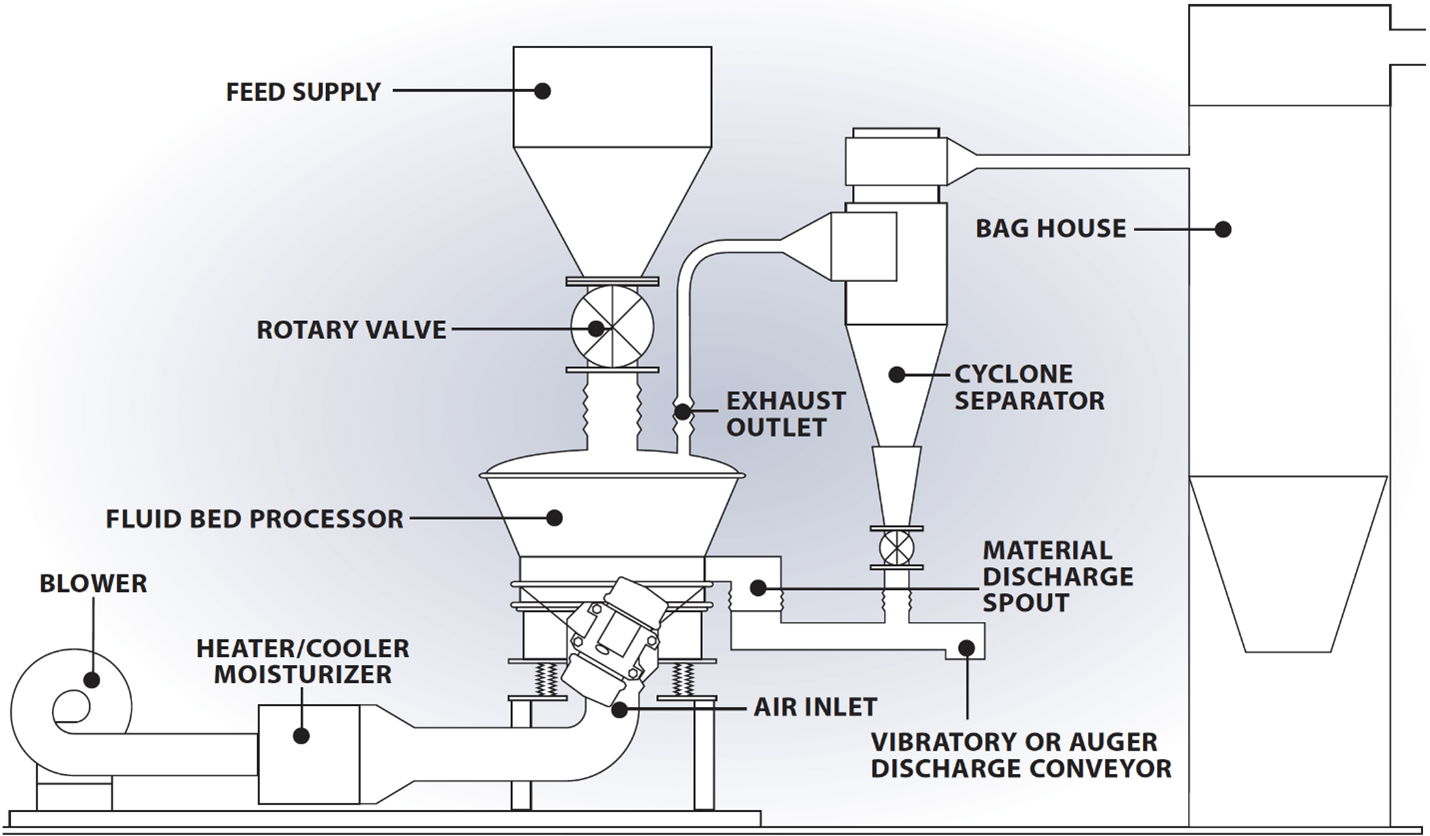

Primary Components: Vibratory Fluid Bed Processors & Systems

In this article, we'll explain the types, benefits, & components of fluid bed systems and processors. For more questions, please contact our team directly.

What is a Fluid Bed Processor?

A fluid bed processor is a versatile piece of equipment that works on the principle of fluidization. Fluidization means small particles or granules of solids subjected to a gas flow to convert the solid-like state of a static bed to a dynamic fluid-like state.

Topics: Fluid Bed Processors, Technical Articles

While the cannabis industry continues its rapid growth (with global sales expected to reach $33.6 billion during the next three years), the fact remains that raw cannabis is inherently difficult to handle. It is both expensive and fragile, making initial sorting a critical path item in terms of productivity and profitability. Small and large operations can benefit from investing in sorting technology from an established manufacturer that is highly efficient,flexible and completely field-proven over many years -- in short, a cost-effective way to producea higher quality product with higher throughput and less waste.

Topics: Circular Vibratory Screeners, Cannabis & Hemp Industry

Making the Grade: Screen Nuts for Quality & Classification

Consumers seeking healthier snack options or better-for-you plant-based proteins have been steadily increasing the demand for nuts for decades. There are more than 20 types of edible nuts in the world, with a market value estimated to reach $459.1 billion by 2030.

Varieties include almonds, peanuts, walnuts, pecans, pine nuts, macadamias and more. Each type of edible nut and each stage of the supply chain from "farm to fork" requires sorting to meet size, quality and purity standards, all while maintaining high throughput.

Topics: Sanitary Equipment, Circular Vibratory Screeners, Pet Food Industry

Posts by Tag

- Circular Vibratory Screeners (14)

- Aftermarket & Spare Parts (12)

- Centrifugal Sifters (9)

- Custom Options (6)

- Fluid Bed Processors (4)

- Industrial Screeners & Industrial Sifters (4)

- Vibratory Screeners (4)

- Mixers (3)

- Pet Food Industry (3)

- Screening Questions (3)

- Technical Articles (3)

- Aquaculture Industry (2)

- Blenders (2)

- Cannabis & Hemp Industry (2)

- Sanitary Equipment (2)

- Thermal Processing (2)

- Case Histories (1)

- Coffee Industry (1)

- Distillery & Brewery (1)

- case study (1)

.jpg)