In this article, we'll explain the types, benefits, & components of fluid bed systems and processors. For more questions, please contact our team directly.

What is a Fluid Bed Processor?

A fluid bed processor is a versatile piece of equipment that works on the principle of fluidization. Fluidization means small particles or granules of solids subjected to a gas flow to convert the solid-like state of a static bed to a dynamic fluid-like state. The fluid bed processor can be utilized for applications like drying, cooling, agglomeration, and de-agglomeration. Kason fluid bed systems employ an innovative circular processing unit that is inherently stronger, lighter, and less costly to build—and finish to sanitary standards—than rectangular units having equivalent surface area. Because the circular fluid bed processor is also more compact, complete fluid bed systems can be pre-engineered and preconfigured on caster-mounted frames, ready for installation and start-up. Moreover, Kason circular fluid bed processors maintain an unprecedented operating efficiency across a wide range of model sizes for laboratory and pilot plant testing as well as batch or high-volume in-line drying, cooling, or moisturizing of bulk foods, pharmaceuticals, and chemicals.

What are the types of fluid bed systems?

Depending on the application, a fluid bed processor can be used for continuous or batch mode. Vibratory fluid bed systems are ideal for drying and cooling systems and are available in a range of sizes, from 24-84 inches (610-2540 mm) in diameter. For processors, this translates to a great range of flexibility regarding both small batches and large continuous throughput applications.

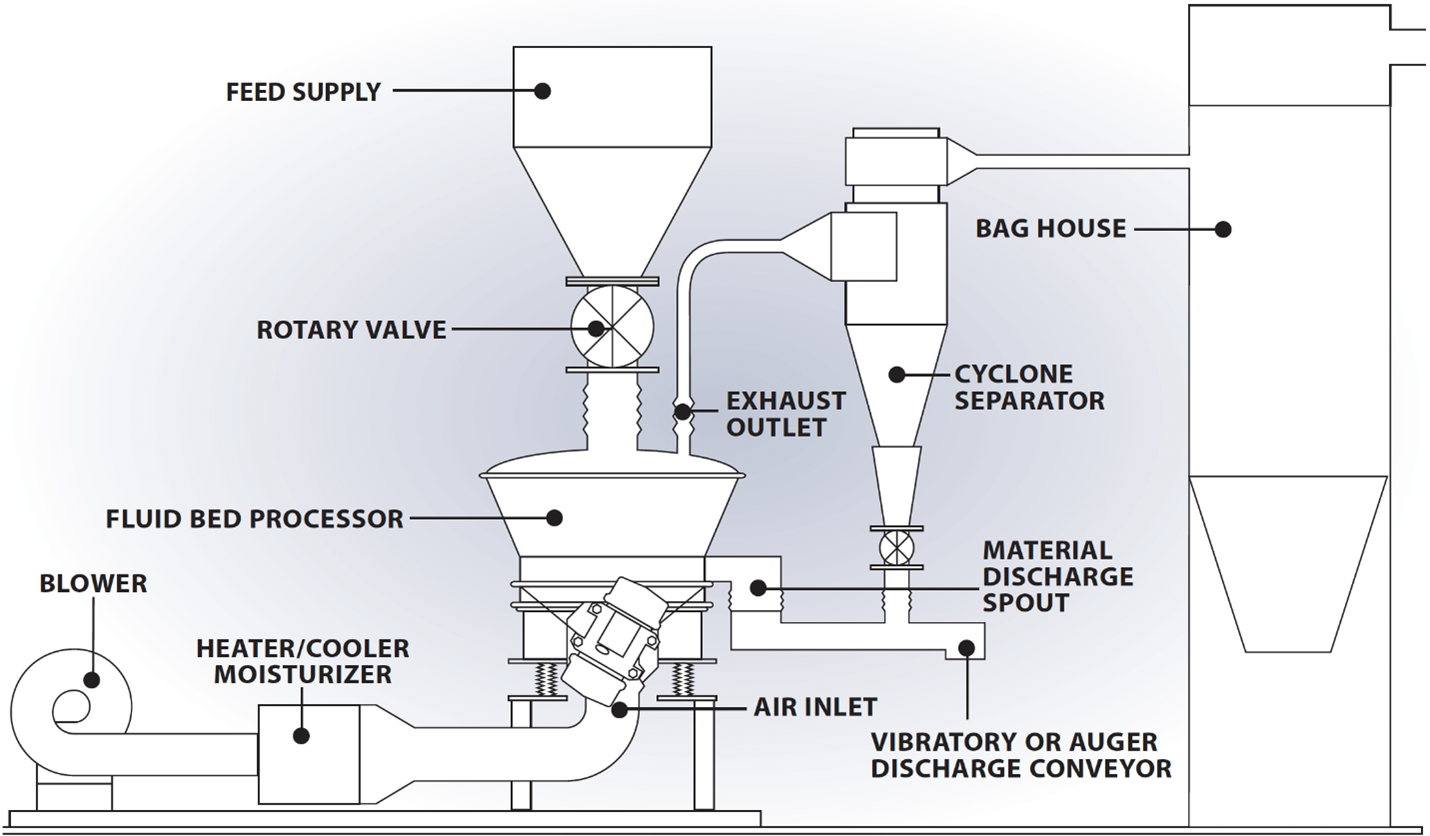

What are the components of fluid bed systems?

For any fluid bed system, the main components can be narrowed down to air supply, heater (if drying), air distributor plate, feed supply, dust separation, and collection and control panel with options of spray manifolds, dehumidifiers, external and internal agitation (either vibrator motors or an impeller/agitator). Fluid bed systems come in various shapes; rectangular and circular beds are the most common.

- Feed Supply: Loads/ feeds the material into the fluid bed system. For circular systems, the material is usually center dropped for continuous application. For rectangular beds, the material comes from one side and leaves from the other end.

- Rotary Valve: Also known as rotary feeder, Controls the incoming feed. Once hooked to the control system, we can precisely monitor and control the feed rate from a drum/tank/hopper into the conveyor or in our case, the fluid bed processor.

- Exhaust Outlet: Provides an outlet for the hot gases to leave the system. Design and selection of exhaust fan should be done carefully, as low suction could increase pressure in the bed processor and hot gases escaping from the discharge spout. Alternately, high exhaust suction could result in loss of material escaping along with exhaust gas.

- Fluid Bed Processor: Facilitates fluidization; depending on the application, the material is processed accordingly. It comprises an air distributor plate, gyratory motors, a spacer frame, an expansion chamber, and a discharge spout with a spray manifold (optional).

- Air distributor plate: Helps uniformly distribute air and prevents material from falling below. Most commonly, three types of distributor plates are found. They are

- Standard perforated plate

- Wire mesh

- Directional plates

- While wire mesh offers the highest open area, directional plates have the advantage of dictating the flow of the material by introducing air tangentially, which generates a swirling motion in the bed. Some studies have also shown that drying time reduces slightly when using a directional plate compared to the other two. One major con of a directional plate is cost. For most applications, wire mesh serves as a balance between efficiency and cost.

- Gyratory motors: shakes the fluid bed processor vertically and horizontally. The vibrations help reduce the pressure drop across the fluid bed, reduce the minimum velocity for fluidization, and move the material in a spiral manner. Thus, the material properties such as temperature and moisture content are uniform throughout the bed. This is a major advantage of using a circular fluid bed dryer. The frame rests on the spring, which isolates vibration from the support structure but allows the fluid bed processor to move easily.

- Spacer frame: The spacer frame can be selected per the needs of the application, thus making the system more customizable.

- Expansion chamber: Reduces the air velocity leaving the system. If the exit velocity isn’t reduced, more material will be lost from the system.

- Material Discharge Spout: Directs the material out of the fluid bed. A weir is used to adjust the bed depth, while a plow gate helps discharge the material quickly.

- Blower/Supply fan: A fan delivers fresh air into the system. A supply and return fan selection are paramount in a fluid bed dryer. The wrong selection of fans could lead to catastrophic system failure or suboptimal performance. The minimum fluidization velocity, as the name suggests, is the air/gas velocity at which the static bed fluidizes and is primarily dictated by the particle size, shape, bulk density, and moisture content, among others. A fan for processing shreds of mozzarella cheese may be too big for processing fine collagen powder, and similarly, a fan for drying insect larvae powder may be smaller for drying large chunks of wet hemp leaves. VFDs or variable frequency drives control the fan motors, so the user has the freedom of scaling up the batch size or bed depth and material feed rate to increase throughput to some extent.

- Heater/Cooler Moisturizer: In any fluid bed processor, the heater/cooler uses the maximum energy among other components. Depending on the application, the air from the supply fan is subjected to a heater/cooler and humidifier/dehumidifier. This treated air is the transport medium for heat and mass transfer to and from the material. This helps control the temperature and humidity of incoming air. The knowledge of psychrometrics plays a key role in determining heat requirements and maintaining appropriate humidity in the air stream. People famously say that every fluid bed scientist is a weatherman! For drying applications, generally, a dehumidifier is used if the material must be processed at a maximum of 80-90 F. A primary example is the drying application in dairy, as well as hemp industry, where cheese and Hemp leaves must be below a certain temperature else, can result in oozing the saturated fat in cheese as well as losing cannabinoids and terpenes in hemp leaves and can seriously deteriorate the product. Hence, a dehumidifier must be used in conjunction with a heating element.

- Air inlet: The selection of heater/cooler depends on the conditions from where the air is delivered. If the supply fan is placed outside the building, the year-round temperature and humidity variations must be accounted for when sizing heaters/coolers. If the fan is placed inside a building, the HVAC system in the building must be adjusted accordingly to facilitate the air requirements of the fluid bed processor.

- Cyclone Separator: When dealing with a system with a wide variation in particle size, the fines may be carried over by the air stream. Sometimes from an economic or environmental perspective, the fines must be captured back before venting air into the atmosphere. Hence, cyclone separators and dust collectors are coupled to the exhaust system. Depending on the type of dust, an explosion vent may be required to prevent catastrophic failure. A rotary airlock at the bottom of a cyclone can maintain pressure difference on both sides and dump material into a conveying system that dumps the material back to the fluid bed processor.

- Vibratory or Auger Discharge Conveyor: To transport processed material to the next processing stage.

- Control system: Brains of the system. Monitor incoming air temperature and humidity, adjust heater power accordingly and monitor exhaust temperature and humidity. Speed control for exhaust and inlet fans and the feed into/from the processor. Can also log data.

- Ductwork: Veins of the system. Duct diameter should be chosen carefully, as larger diameter increases cost, smaller diameter increases pressure losses which increases energy demands. Sudden bends/expansions/ contractions should be avoided whenever possible.

- Air-lift system: Raises the spacing frame for easy cleaning/maintenance, reducing downtime.

What are the benefits of fluid bed processors?

- Compact, less footprint

- Less expensive than the rectangular counterpart

- Uniform material processing as by design, no sharp edges/corners

- Lower cleaning time

- Versatile, can be modified for agglomeration if needed

- Lower energy requirements

Conclusion

When sourcing a vibratory fluid bed dryer or cooler, a circular model should be considered for its consistent and efficient drying results, quick-clean sanitary design, smaller footprint, lower initial and operating costs, and reduced downtime. Rectangular options are appropriate in high-volume continuous applications where there is plenty of floor space and the need for pristine sanitation is not highly prioritized. Today’s circular vibratory fluid bed dryers/coolers are available from small-batch pilot plant/lab sizes to larger models suitable for continuous processing applications, offering a wide range of options for most applications.

To learn more about fluid bed systems download the Fluid Bed Dryers, Coolers and Moisturizers Catalog today or contact our fluid bed technical specialists at info@kason.com or by calling 973-467-8140.